ABOUT CORIAN®

Key features:

- Resistant

hygiene-critical or high-traffic. nonporous

RESISTANT

Since its introduction in 1967, DuPont™ Corian® has proved itself to be a remarkably durable material that is easy to live with. It cannot delaminate and stands up well to daily wear and tear. It resists most of the impacts, nicks and cuts that occur in heavy traffic areas. DuPont™ Corian® has been tested for its mechanical, thermal, electrical and other surface properties. Results of these specific tests as well as details on the other physical properties of DuPont™ Corian® can be consulted in the “PERFORMANCE PROPERTIES” in the technical section of this website.

INCONSPICUOUS JOINS

The applications for DuPont™ Corian® are limited only by the imagination. Pieces of Corian® can be glued together inconspicuously to create a seamless look, giving virtually unlimited design possibilities for surfaces. Long counters, for example, can be made easily in lightweight pieces in a workshop and then joined together at the installation site. Edges can be built up to appear thicker.

REPAIRABLE

Surfaces in DuPont™ Corian® are renewable, meaning they can be fully restored with ordinary mild abrasive cleansers and a scouring pad. Cigarette burns, for example, can be easily removed in this way. Damage caused by abuse can usually be repaired on site without having to completely replace the material.

NON-TOXIC

DuPont™ Corian® is an inert and non-toxic material. Under normal temperature conditions, it does not emit gases. When burned, it releases mainly Carbon Oxides and the smoke generated is optically light and does not contain toxic halogenated gases. Because of these properties, DuPont™ Corian® is used in public areas and for sensitive applications such as airport check-in counters, walls and work surfaces in hospitals and hotels.

THERMOFORMABLE

DuPont™ Corian® can be thermoformed in wooden or metal moulds at controlled temperatures in order to create various 2D and 3D design objects. Embossing effects can also be created using the Bas Relief technique.

TRANSLUCENT

The translucency of DuPont™ Corian® is especially striking in the lighter colours as well as with thinner sheets. Many designers are now using the material to create lamps or lighting effects in various applications. The new colour family, called the Illumination Series, consists of colours in 6 mm and 12 mm sheets featuring enhanced translucency to be used for creating special lighting effects.

WORKABLE LIKE WOOD

DuPont™ Corian® can be worked like hardwood and using similar tools. Most DuPont™ Corian® fabricators originally trained as carpenters.

ENVIRONMENTALLY FRIENDLY

DuPont™ Corian® is manufactured in compliance with strict standards in order to limit waste and energy consumption at all stages of the production process. Both the material itself and the adhesives and sealants used to install it are GREEN GUARD Indoor air quality certified® for producing low VOC emmisions as well as being Green Tag certified.

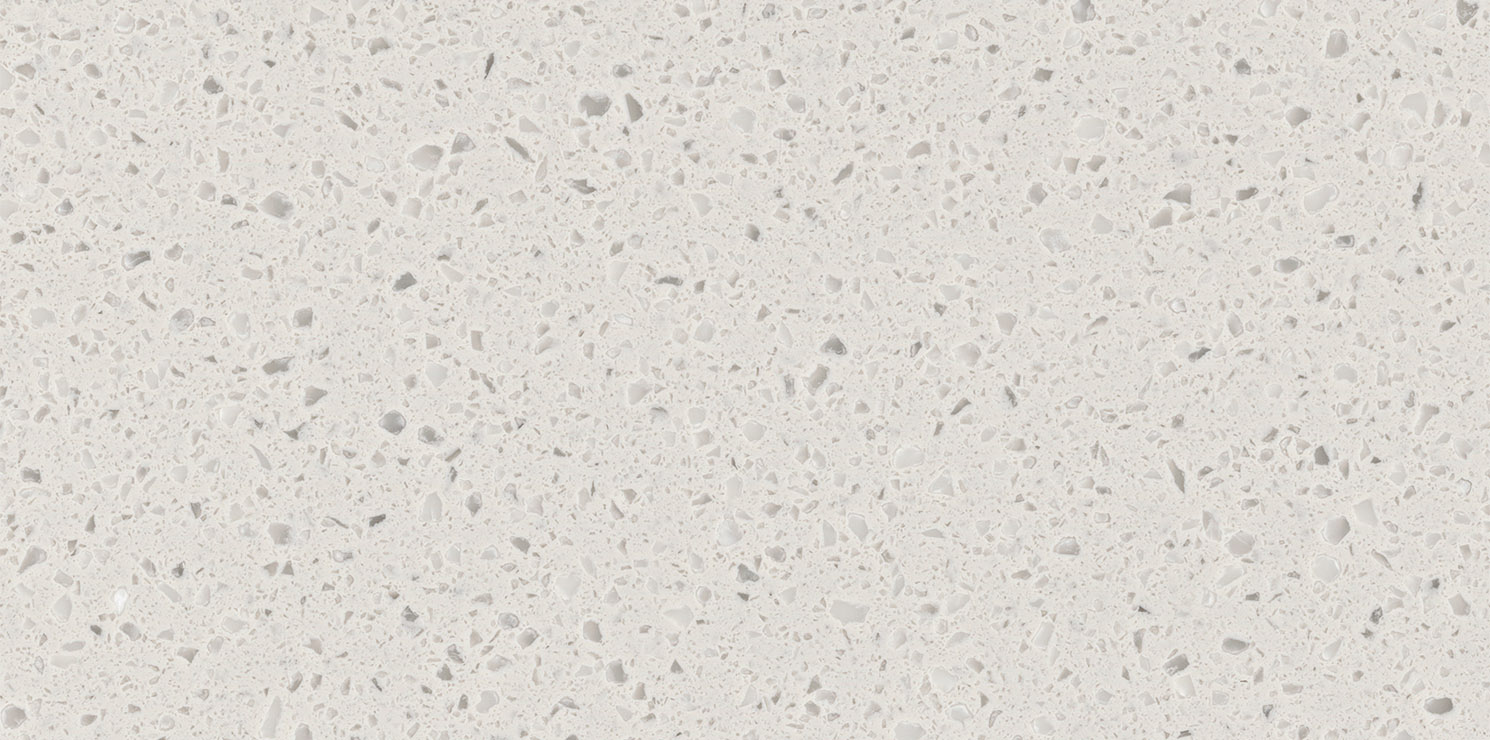

SOLID

Colours and textures run through the entire thickness of the material and cannot wear away. DuPont™ Corian® is a solid material and cannot delaminate.

COLOURFUL

The refined colours of Corian® allow for a creative and inspired working palette of solid, textured and translucent hues. You can choose a single colour; a neutral basis for design; or experiment with eye-catching harmonies. Corian® can also be used as inlays, accents, or as a versatile complement to other materials such as metal, wood, stone, glass, etc. Corian® can also be sublimation printed with any digital image.